The future of materials lies not in static, manufactured systems, but in living materials that can grow, adapt, and respond to their environment. Our research thrust in Engineering Living Materials and Biological Systems combines agent-based modeling, molecular dynamics simulations, and high-performance computing to design microbial consortia and biological assemblies with unprecedented material properties. Our research aims to reveal how pathogenic bacteria invade human gut mucus through nanoscale mechanical forces, informing new therapeutic approaches. We are pioneering microbe-based living materials with programmable mechanical properties, engineering biofilms for self-healing infrastructure, and decoding biopolymeric systems for multifunctional bio-inspired materials. By understanding biological assembly mechanisms computationally, we create materials that function more like living organisms: responsive, adaptive, and environmentally integrated.

The future of materials lies not in static, manufactured systems, but in living materials that can grow, adapt, and respond to their environment. Our research thrust in Engineering Living Materials and Biological Systems combines agent-based modeling, molecular dynamics simulations, and high-performance computing to design microbial consortia and biological assemblies with unprecedented material properties. Our research aims to reveal how pathogenic bacteria invade human gut mucus through nanoscale mechanical forces, informing new therapeutic approaches. We are pioneering microbe-based living materials with programmable mechanical properties, engineering biofilms for self-healing infrastructure, and decoding biopolymeric systems for multifunctional bio-inspired materials. By understanding biological assembly mechanisms computationally, we create materials that function more like living organisms: responsive, adaptive, and environmentally integrated.

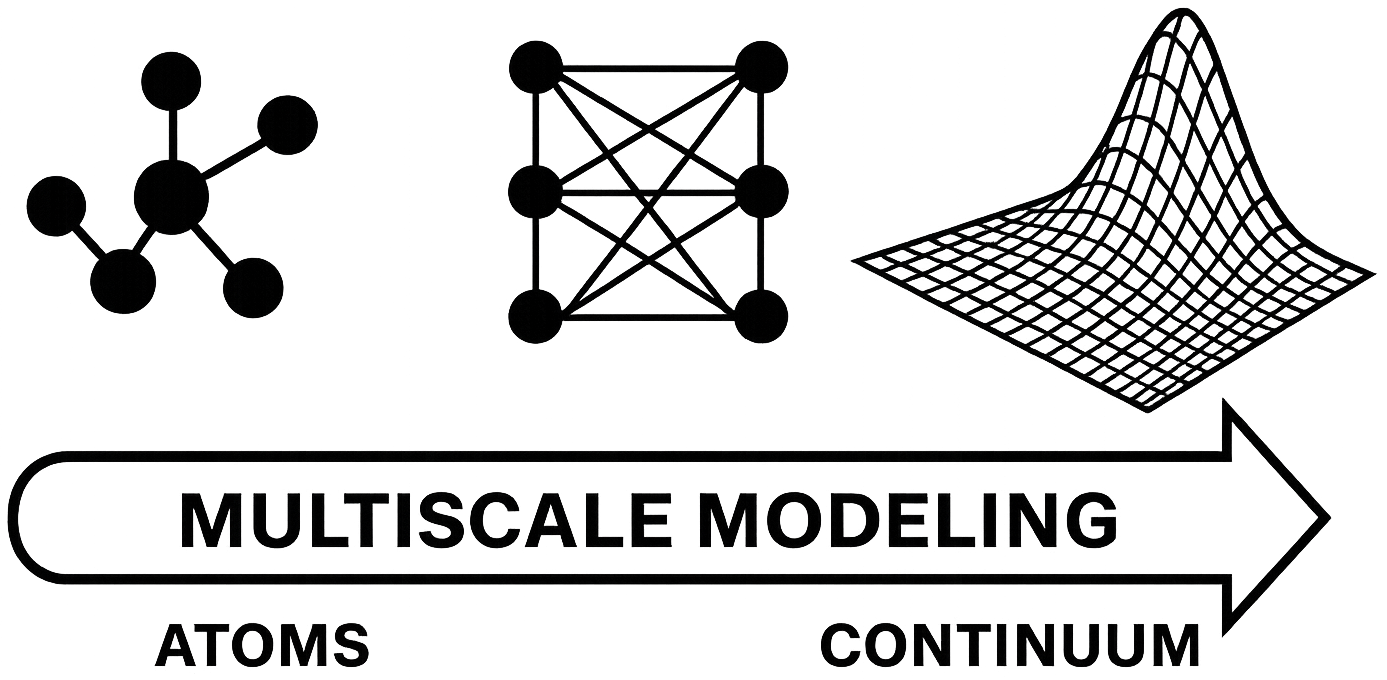

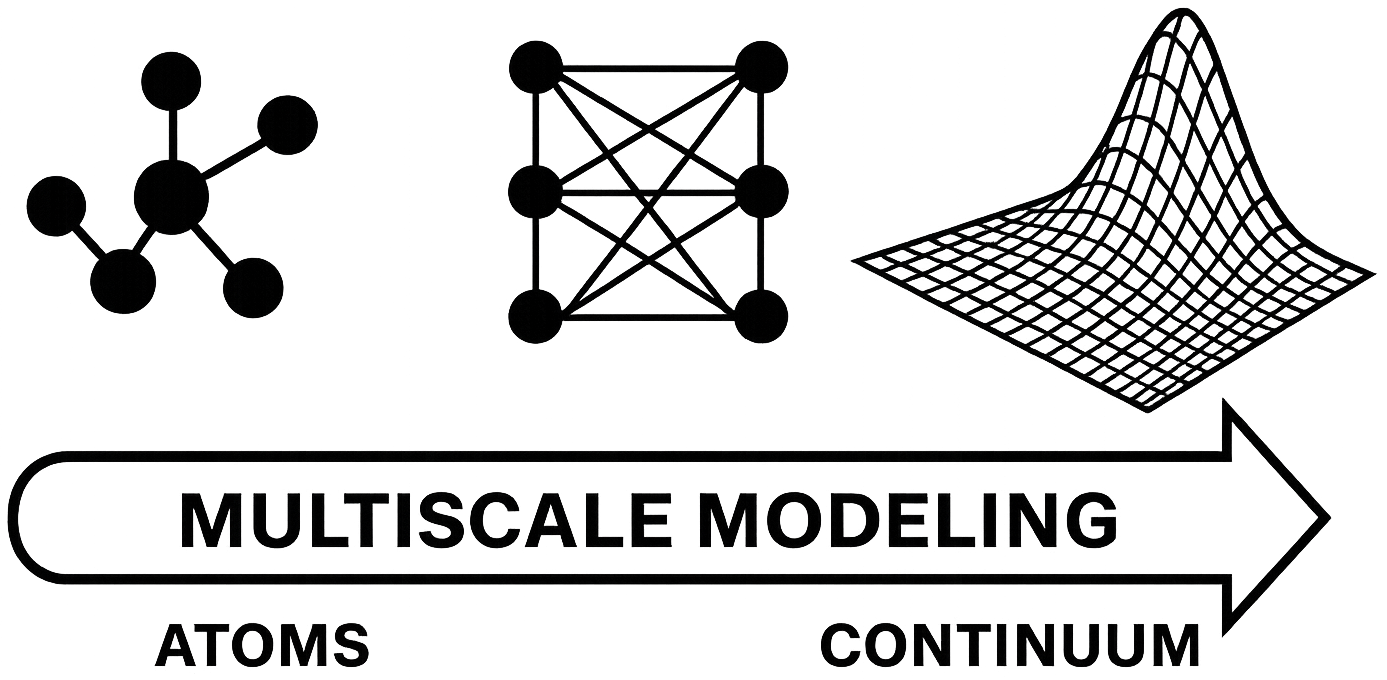

The complexity of modern materials demands computational approaches that can navigate vast design spaces while maintaining physical accuracy and reliability. Our research thrust in Multiscale Computational Materials Science and AI/ML develops next-generation computational tools that integrate artificial intelligence with physics-based modeling across all relevant scales. We pioneered the first application of Kolmogorov-Arnold Networks to train interatomic potentials for molecular dynamics models, achieving superior prediction accuracy while reducing computational complexity. Our Gaussian process metamodeling enables rapid exploration of complex material parameter spaces that would be prohibitive with traditional methods. Our multiscale integration capabilities seamlessly connect quantum mechanical calculations (DFT) with atomistic simulations (molecular dynamics) and continuum modeling. Applied to systems ranging from lithium-ion conductors to structural materials, this approach enables device-scale predictions grounded in fundamental quantum mechanical insights. This comprehensive computational approach accelerates materials discovery while maintaining the reliability essential for real-world applications.

The complexity of modern materials demands computational approaches that can navigate vast design spaces while maintaining physical accuracy and reliability. Our research thrust in Multiscale Computational Materials Science and AI/ML develops next-generation computational tools that integrate artificial intelligence with physics-based modeling across all relevant scales. We pioneered the first application of Kolmogorov-Arnold Networks to train interatomic potentials for molecular dynamics models, achieving superior prediction accuracy while reducing computational complexity. Our Gaussian process metamodeling enables rapid exploration of complex material parameter spaces that would be prohibitive with traditional methods. Our multiscale integration capabilities seamlessly connect quantum mechanical calculations (DFT) with atomistic simulations (molecular dynamics) and continuum modeling. Applied to systems ranging from lithium-ion conductors to structural materials, this approach enables device-scale predictions grounded in fundamental quantum mechanical insights. This comprehensive computational approach accelerates materials discovery while maintaining the reliability essential for real-world applications.

Nature has evolved remarkable materials through billions of years of optimization, achieving properties that surpass many engineered systems. Biology represents the ultimate materials laboratory, having evolved sophisticated materials through billions of years of optimization. Our research thrust in Bio-Inspired Materials for Sustainability and Applications decodes these natural design principles and translates them into sustainable engineered materials that address critical global challenges. We reverse-engineer these biological design principles to create sustainable materials for engineering applications. We computationally characterized silk-based biodevices that offer sustainable alternatives to petroleum-based medical materials. We unveiled the molecular mechanisms of supramolecular assemblies that achieved record ionic conductivities for next-generation battery electrolytes. We probed the mechanisms for engineering collagen scaffolds with controlled fiber alignment for tissue regeneration and developing 2D materials for water treatment applications. By learning from biology's optimization strategies, we help to create materials that are both high-performing and environmentally sustainable. This thrust represents our commitment to creating a sustainable materials economy where high-performance materials are grown rather than manufactured, waste becomes feedstock, and biological principles guide technological advancement.

Nature has evolved remarkable materials through billions of years of optimization, achieving properties that surpass many engineered systems. Biology represents the ultimate materials laboratory, having evolved sophisticated materials through billions of years of optimization. Our research thrust in Bio-Inspired Materials for Sustainability and Applications decodes these natural design principles and translates them into sustainable engineered materials that address critical global challenges. We reverse-engineer these biological design principles to create sustainable materials for engineering applications. We computationally characterized silk-based biodevices that offer sustainable alternatives to petroleum-based medical materials. We unveiled the molecular mechanisms of supramolecular assemblies that achieved record ionic conductivities for next-generation battery electrolytes. We probed the mechanisms for engineering collagen scaffolds with controlled fiber alignment for tissue regeneration and developing 2D materials for water treatment applications. By learning from biology's optimization strategies, we help to create materials that are both high-performing and environmentally sustainable. This thrust represents our commitment to creating a sustainable materials economy where high-performance materials are grown rather than manufactured, waste becomes feedstock, and biological principles guide technological advancement.

The future of materials lies not in static, manufactured systems, but in living materials that can grow, adapt, and respond to their environment. Our research thrust in Engineering Living Materials and Biological Systems combines agent-based modeling, molecular dynamics simulations, and high-performance computing to design microbial consortia and biological assemblies with unprecedented material properties. Our research aims to reveal how pathogenic bacteria invade human gut mucus through nanoscale mechanical forces, informing new therapeutic approaches. We are pioneering microbe-based living materials with programmable mechanical properties, engineering biofilms for self-healing infrastructure, and decoding biopolymeric systems for multifunctional bio-inspired materials. By understanding biological assembly mechanisms computationally, we create materials that function more like living organisms: responsive, adaptive, and environmentally integrated.

The future of materials lies not in static, manufactured systems, but in living materials that can grow, adapt, and respond to their environment. Our research thrust in Engineering Living Materials and Biological Systems combines agent-based modeling, molecular dynamics simulations, and high-performance computing to design microbial consortia and biological assemblies with unprecedented material properties. Our research aims to reveal how pathogenic bacteria invade human gut mucus through nanoscale mechanical forces, informing new therapeutic approaches. We are pioneering microbe-based living materials with programmable mechanical properties, engineering biofilms for self-healing infrastructure, and decoding biopolymeric systems for multifunctional bio-inspired materials. By understanding biological assembly mechanisms computationally, we create materials that function more like living organisms: responsive, adaptive, and environmentally integrated.